Abrasive Cost Savings in Heavy Equipment Manufacturing

This cost saving analysis is based on a manufacturer of heavy equipment, including tractors, combines, hay tools, sprayers, forage and tillage equipment.

Evaluation and Opportunity

Given the major operations involved with this manufacturer, several locations are utilized within the facilities. Although these operations are kept separate and involve different applications there is still product crossover between the two. Acknowledging heavy stock and rust removal as separate applications, new products can be suggested to improve production efficiencies for said heavy equipment. Although the wire brush that is currently used for specific applications is a formidable solution, many other products can be adjusted or replaced for the benefit of remaining applications.

Billed Time for Rust Removal

Location 1…………………………………………….. 150 hrs/wk

Location 2…………………………………………….. 125 hrs/wk

Combined Total…………………………………………..13,750 hrs/yr

Annual Billed Cost x Labor Rate…………………………. $412,500

Based on performance results and operator feedback, we can estimate the following product rates:

Performance New SCD Annual Improvement Hours/Yr Savings

2 to 1…………………………………………..6,875…………..$206,250

3 to 1…………………………………………..4,583…………..$275,000

4 to 1…………………………………………..3,438…………..$309,375

Product Usage Savings

PREDATOR™ Quick-Lok Disc…………… 39,360………….$9,052

PREDATOR™ Resin Fibre Disc…………. 81,000………….$23,490

Zirconia Resin Fibre Disc……………6,960…………..$7,238

Surface Conditioning Disc……………62,008………….$11,781

Total $51,561

Earth Moving Equipment

This analysis is based from a manufacturer of small earth moving equipment specializing in compact loaders, excavators and attachments.

Evaluation and Opportunity for Heavy Equipment

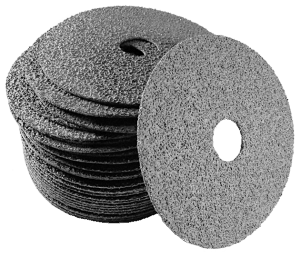

Several production departments were available for evaluation, including booms, mainframes, flat beds and rails. Most operators were using 9” 60 grit resin fiber discs on their various applications, with the addition of a knotted wire brush on certain welds.

The majority of all applications involved removal of large scratches or penetration marks and mill scale on mild steel plates or sheets. Relative to the required applications, large resin fiber discs are far too aggressive and their maximum potential is not realized.

ARC believes that we can provide better performance by product with a better base cost than what is currently being used as evidence in our mounted flap wheel quote and feedback from the heavy equipment operator. We provided a better mounted flap wheel at a $1.53 savings per piece.

ARC identified 3 main products that provide cost savings in cut, life and head to head product savings. ARC was $1.53 less than the current flap wheel that was being used with equal performance. This one item was a $53,000 savings. Additional items such as the resin fiber disc and flap disc showed a faster cut and a 2 to 1 increase in life with a lower product cost.

Check out our social media pages on Linkedin and Facebook to keep up with our weekly updates! Be sure to check out our previous posts in our Daily Grind blog as well!