Case Study: Aerospace Manufacturing And Quick-Loks

PREDATOR™ Performance Coated Quick-Loks were recently involved in a case study to help resolve an issue for a leading aerostructure manufacturer. For a more in-depth analysis, download the white paper and read about how ARC helped improve safety, increase efficiency, and further impact their bottom line.

Overview

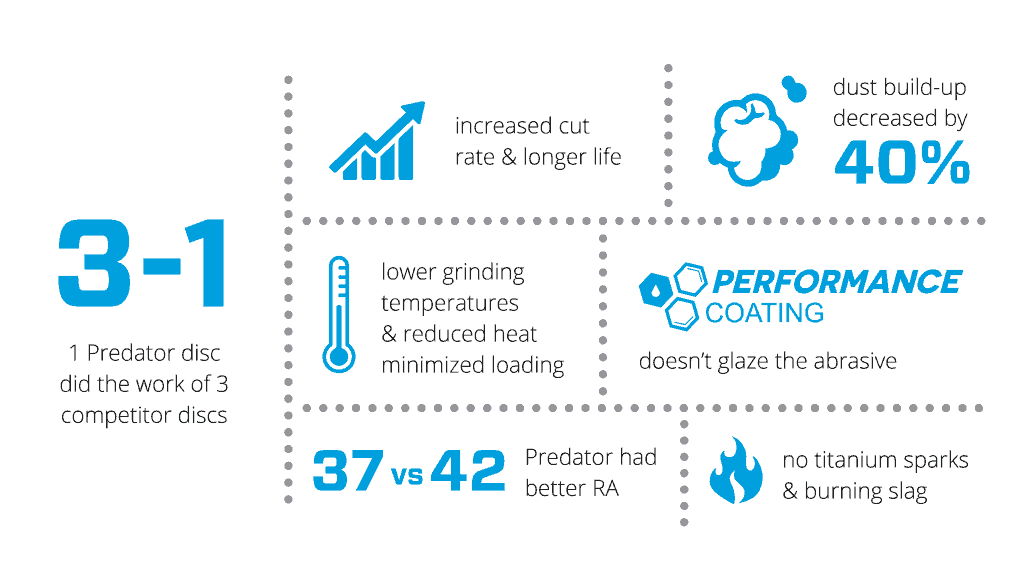

The primary focus was to compare the performance of PREDATOR Quick-Loks to their current quick-change discs. All products were tested on a titanium Bulkhead AP Engine Mount.

Problems

- Current quick-change discs were overheating, burning, and glazing

- Titanium particles melting and flying off disc

- Titanium slag particles melting onto work surface

- Surface conditioning materials needed to clean surface deformities caused by burning titanium slag

- Filtration systems ingesting hot dust particles causing safety hazards

Application

Operators were able to use a 100 grit PREDATOR™ Quick-Lok to achieve the same desired finish from the use of the competitor’s 60 grit disc and medium surface conditioning disc. This resulted in less product used and an expedited process.

CONCLUSION

results

Product Overview

PREDATOR Quick-Loks outlast the competition by adding additional self-sharpening grains to the top layer of the disc. The addition of Performance Coating reduces the loading and heat generation of aluminum and other soft metals and increases performance average 3-to-1 over uncoated material.

If you want to learn more about PREDATOR and its offerings, head over to the brand page.

For more information on how Performance Coating can impact your business, check the video out below and see the difference!

Also check out our social media pages on Linkedin and Facebook to keep up with our weekly updates!