Case Study: AUTOMOBILE MANUFACTURER ANd QUICK-Loks

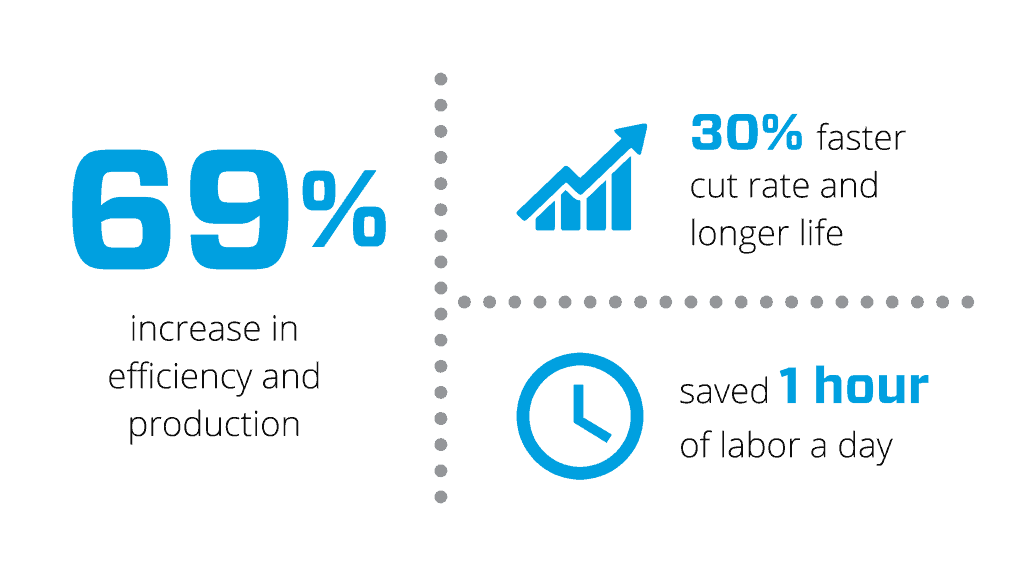

PREDATOR™ Resin Fiber Quick-Loks were recently involved in a performance test case study for a leading automobile manufacturer. For a more in-depth analysis, download the white paper to read about how ARC helped increase production and efficiency to further impact their bottom line.

Overview

The primary focus was to compare the performance of PREDATOR™ Resin Fiber Quick-Loks to their current quick change discs. All products were tested deburring door trim frames with a right angle grinder.

CHALLENGES

- Performance and efficiency of current quick-change discs

- Current quick-change discs becoming too hot and glazing

- Current disc material shelling and deteriorating

- Frequent changeovers

Application

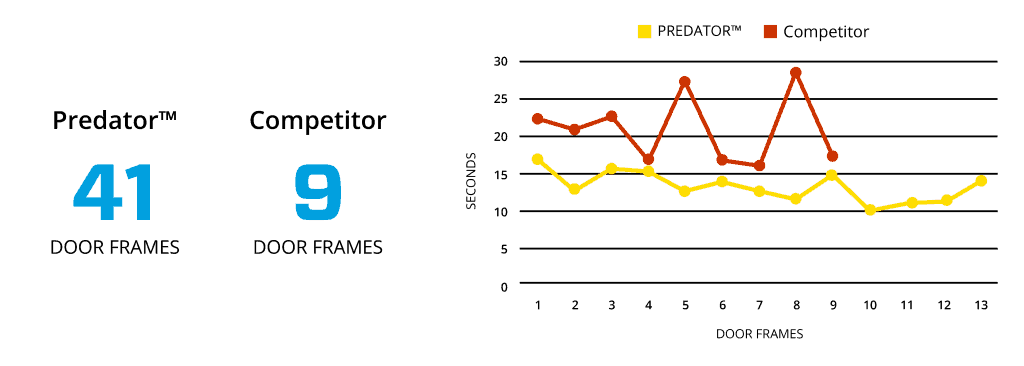

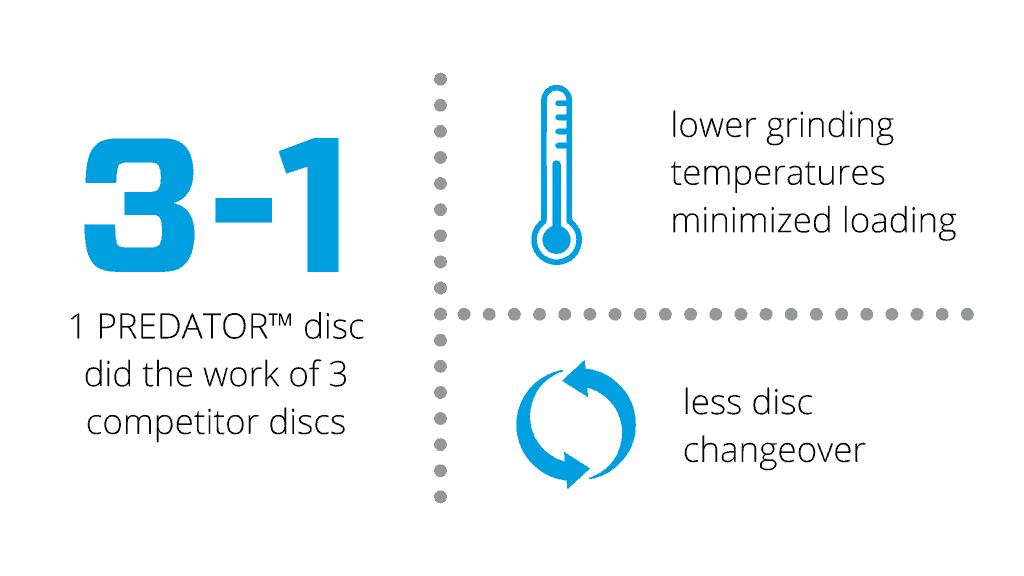

Operators used one Resin Fiber 24 grit PREDATOR™ Quick-Lok to complete more door frames and each door frame quicker than four of the competitor’s 24 grit ceramic quick change discs. Cooler grinding temperatures of the PREDATOR™ Quick-Lok prevented shelling or deteriorating. This resulted in less disc changeover and expedited production.

PERFORMANCE TEST

CONCLUSION

results

PREDATOR™ Quick-Loks outlast the competition by adding additional self-sharpening grains to the top layer of the disc. The integrated grinding aid provides a long lasting, aggressive cut for the life of the disc.

Learn more about how Resin Fiber Quick-Loks and other in-demand ARC products can be available faster than ever before with ARC Arrive™.

ARC Arrive™ features our 500 fastest moving, high-performance products, with new favorable pricing and available for 48 hour shipment.

Coming August 2019

Also check out our social media pages on LinkedIn and Facebook to keep up with our weekly updates!