Case Study: Mild Steel Frames and Cut Off Wheels

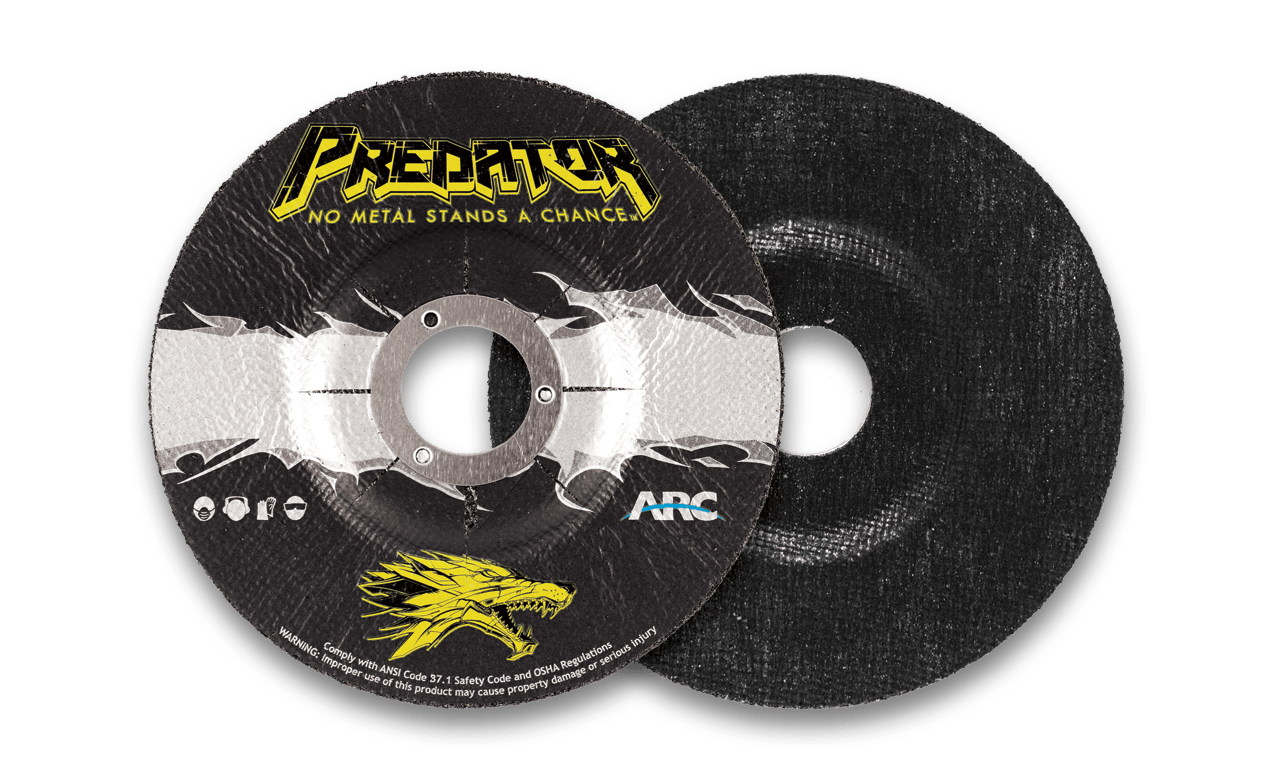

ARC Abrasives teamed up with a leading manufacturer of wood and coal-fired heaters to test the effectiveness of our PREDATOR™ cut off wheels against their current bonded discs. Our cut off wheels were tested on mild steel frames that create the framework and body of wood-burning stoves. To learn more, download the white paper to read about how ARC helped increase production and efficiency to further impact their bottom line.

Challenges

The primary focus was to compare the performance of our cut off wheels to the current discs being used. Their current bonded discs had issues with performance and efficiency, as well as frequent changeovers. The resulting performance issue created an inconsistent quality, as well as inaccurate and slow cuts.

Although the currently used disc was getting the job done, questions were raised in the possibility of a more efficient product that could increase input while improving cut quality and performance.

Application

Operators were able to use the PREDATOR cut off wheels to get a more precise cut on the mild steel frames with positive results. There was a noticeable difference in the quality and speed of the product, as one disc was able to produce twice as many pieces.

Conclusion

Changing to our PREDATOR cut off wheels brought on an annual $2,800 in cost savings. The best outcome came from the more precise application and improved performance, resulting in a 30% cut speed increase. The cut off wheels producing more pieces showed that fewer changeovers were needed.

Also check out our social media pages on LinkedIn and Facebook to keep up with our weekly updates!