ARC Engineered Solutions: Coated Overview

The cutting power of an abrasive grain is dependent upon shape, hardness, toughness, and orientation. All four factors control the penetration of cut, and the life of the grain. The shape of the grain governs the cutting efficiency. Sharper grains produce a cleaner cut and tend to stay cooler during use. Blocky grains give a rougher cut, and create more friction on the workpiece. It is understood that different applications require different types of abrasive grain.

The wear characteristics of non-woven abrasives are different from coated abrasives. In use, the abrasive grain within coated abrasives wears down and changes shape – resulting in different scratch patterns.

Coated Abrasives

Coated abrasives are made by bonding an abrasive grain to a backing material using a make coat of resin. A second coat (size coat) of resin, and sometimes even an additional coat (top size coat), is applied. After curing in an oven, the material is converted into various types of abrasive products including discs, fiber discs, rolls, belts, flap discs and flap wheels.

ARC’s coated abrasives are used in an extensive range of applications from grinding and deburring to surface prep and finishing.

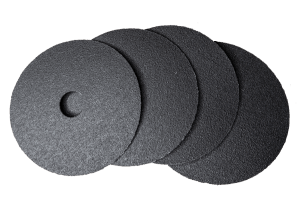

Resin Fiber Discs

A resin fiber disc is intended for aggressive applications, but the grain structure can determine the product life. Its rigid backing improves grain retention while its orientation reduces clogging.

Available Grains:

- Ceramic

- PREDATOR resin fiber

- Aluminum Oxide

- Zirconia Alumina

Flap Discs

Flap discs provide the added benefit of finer finishing after aggressive grinding. The consistent removal rate and speed of cut makes it suitable for stainless steel applications. We offer our flap discs in plastic, fiberglass, and aluminum backings.

Available Grains:

- Ceramic

- PREDATOR

- PREDATOR mini

- Aluminum Oxide

- Zirconia Alumina

Quick-Change Discs

Quick-change discs are engineered with different styles of locking mechanisms to provide a fast disc changeover. Our quick and easy attachments come in an R-lock and S-lock, and their ideal size and shape are optimal for working in small, restricted areas.

Available Grains:

- AMBUSH Ceramic

- PREDATOR

- PREDATOR resin fiber

- Aluminum Oxide

- Zirconia Alumina

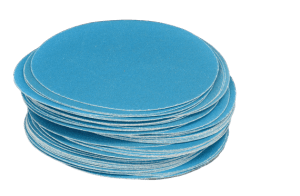

PSA Discs

Our paper discs are available in both disc rolls, or boxed together with a liner and tab. Their reduced cost and fine finish make this an easy choice for metalworking specialists to get the job done.

Available Grains:

- PREDATOR

- Aluminum Oxide Cloth

- Aluminum Oxide Film

- Zirconia Alumina

- Zirconia Alumina +

- SPECTRA White

- SPECTRA Gold

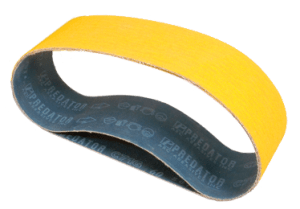

Belts

Abrasive belts are suitable for various grinding and sanding operations that can range from mild stock removal, to fine finishing. All belts are made with high tensile strength backing and closed coat for maximum stock removal.

Available Grains:

- AMBUSH Ceramic

- PREDATOR

- Aluminum Oxide

- Zirconia Alumina

- Zirconia Alumina +

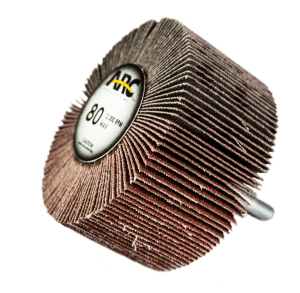

Flap Wheels

Mounted and unmounted flap wheels are a great choice for light grinding, blending, deburring, and finishing applications on a variety of metals. Our flap wheels are offered with a high quality cotton backing. They are designed to wear, slowly exposing new grain.

Available Grains:

- Aluminum Oxide

Cartridge Rolls

Cartridge rolls are ideal for accessing small enclosed spaces. As they wear, the wrapped layers continually expose new abrasive layers for consistent cutting action. Its high quality backing results in a longer product life, as the material wears evenly for a consistent and smooth operation. We offer our cartridge rolls in straight or tapered form.

Available Grains:

- Aluminum Oxide

- Zirconia Alumina

Pads

Square and cross pads are also ideal for small, tight, and enclosed locations. As they wear, the wrapped layers continuously reveal abrasive grains for consistent cutting action. We also offer our pads with an eyelet for quick changeover.

Available Grains:

- Aluminum Oxide

Check out our social media pages on Linkedin and Facebook to keep up with our weekly updates!