Mild Steel Rust Removal and Product Choice

While steel is the most common and heavily manufactured material in the world, there is always the major flaw of rust. Any material with iron that gets exposed to oxygen and water will cause the form of corrosion. Mild steel, also known as carbon steel, will rust unless treated with a protective coating – and that only slows the process. If you are faced with this issue and need assistance with aggressive rust removal, ARC Abrasives has the products that can help.

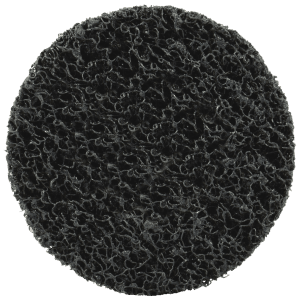

We recommends on using ARCSTRIP for the removal of rust on mild steel. ARCSTRIP will remove loose material such as rust and mill scale without affecting the base material. Our coarse hook and loop discs can also be used but will not be as aggressive as the ARCSTRIP product. Both ARCSTRIP and non woven hook and loop will remove the rust without loading, contributing to longer life compared to a coated abrasive for this application.

Operation and Tools on Mild Steel

Depending on the product, the operation will consist of the use of a right angle grinder, or a backing pad if a hook and loop is used. You will commonly see a wide range of right angle grinders for this application due to ease of use and aggressive rust removal on mild steel.

Critical Points

Plate and structural steel will usually only have rust removal around the weld area as most of the plate and structural steel will not be painted, but only primed. For that application, you will mostly see wire brushes cleaning rust before the area is welded. ARCSTRIP will work best for light rust on thinner mild steel plates, structural and sheet products. Non woven will work best on large areas of removal and contoured shapes.

Check out our social media pages on Linkedin and Facebook to keep up with our weekly updates!