Case Study: PREDATOR Belts and the Automotive Industry

ARC Abrasives teamed up with a supplier of advanced automotive technology to test the effectiveness of our PREDATOR Ceramic Hybrid belts to their current standard grain belts. All products were tested on aluminum and steel components for the automotive hybrid market. To learn more, download the white paper to read about how ARC helped increase production and efficiency to further impact their bottom line.

Overview

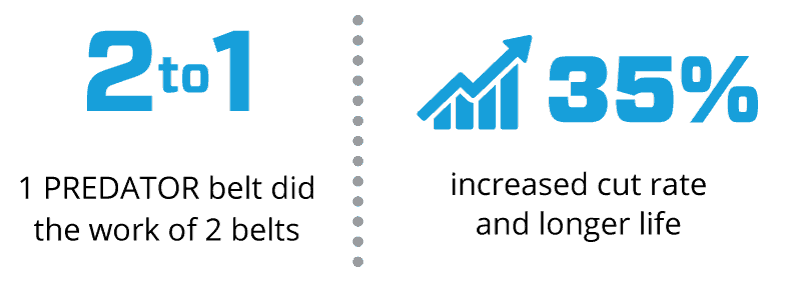

The primary focus was to compare the performance of our belts to the current belts being used. The challenges that the company faced involved:

- Using 2 belts to get consistent and efficient results

- Frequent changeovers due to the product life

Application

Operators were able to use a PREDATOR belt for a more aggressive cut in comparison to the zirconia alumina belts. The performance quality of the PREDATOR belt resulted in a longer product life.

Conclusion

Results

PREDATOR Belts in the metalworking industry

Belts are used in multiple applications that range from fine finishing of stainless steel coil, to heavy stock and weld removal. Heavyweight Y-weight are used for stock removal, while flexible J-weight is used for fine finishing and contour work. J-weight materials are not available in coarse grits coarser than 60.

PREDATOR belts have a heavy Y-weight backing and proprietary grain structure, ensuring quality performance on a wide range of alloys. The combination of two grinding aids only reinforces its leading gram removal ratio.

Also check out our social media pages on LinkedIn and Facebook to keep up with our weekly updates!