Case Study: Quick-Loks and Automotive Door Frames

ARC Abrasives teamed up with a leading automobile manufacturer to test the effectiveness of PREDATOR™ Resin Fiber quick-loks to their current ceramic quick-change discs. Our quick-lok products were tested for deburring automotive door trim frames using a right angle grinder. To learn more, download the white paper to read about how ARC helped increase production and efficiency to further impact their bottom line.

Challenges

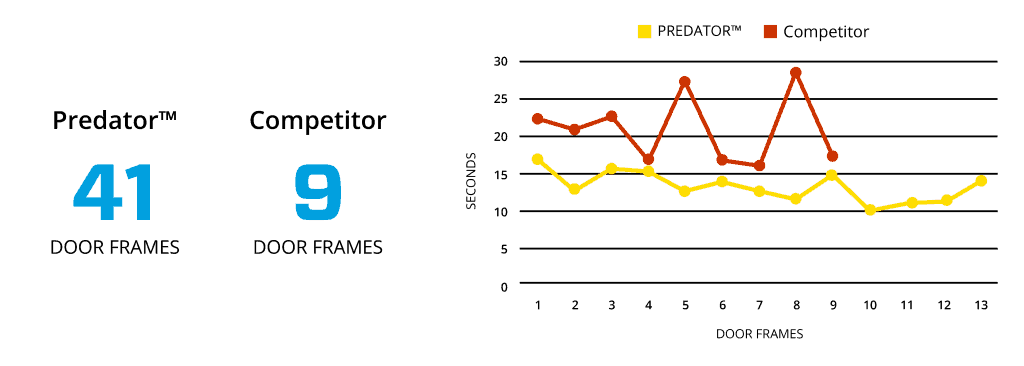

The primary focus was to compare the performance of our quick-loks to the current discs being used. Their current quick-change discs had issues with performance and efficiency, due to the product material shelling and deteriorating. This critical problem was caused by the discs becoming too hot and glazing over, resulting in frequent changeovers.

Application

Operators were able to use a PREDATOR Resin Fiber quick-lok disc on an automotive door frame with a right angle grinder. The disc showed a noticeable improvement on stock removal and deburring. Operators were able to complete each door frame faster and more door frames than their current ceramic disc.

Conclusion

Changing to our PREDATOR quick-loks brought on a 69% increase in efficiency and production. The best outcome came from the lowered grinding temperatures and fast cut rate, resulting in saving 1 hour of labor a day. The PREDATOR discs having minimized loading resulted in less changeover for the operators.

PREDATOR™ Quick-Loks outlast the competition by adding additional self-sharpening grains to the top layer of the disc. The integrated grinding aid provides a long lasting, aggressive cut for the life of the disc.

Also check out our social media pages on LinkedIn and Facebook to keep up with our weekly updates!