Resin Fiber Discs: Product Highlight

Resin fiber discs are flat discs used for heavy grinding and weld removal. Resin fiber discs consist of a stiff fiberboard backing coated with single layers of resin and abrasive. ARC’s resin fiber discs have exceptional grinding aids for a more agile cut. This grinding aid helps performance and keeps the disc cool during grinding. The resin fiber discs have an arbor hole to allow them to be attached to a back-up pad for better usage.

Resin Fiber Disc Performance

Uses and Advantages

Resin fiber discs are used for heavy stock removal on electric and pneumatic angle grinders. They have a limited life span due to the product being two-dimensional and having a single layer of grit. Resin fiber discs can be discarded once the grit loses its sharp edge. Unlike flap discs, no new abrasive is exposed as the surface wears down.

Heat Build Up and Prevention

Excessive heat during use causes two major problems:

- Local heating can blacken the metal surface and damage the surface structure

- Excessive heat shortens the product life

Selecting the Right Disc for the Job

- Choose a disc with a self sharpening grain such as zirconia or ceramic. If the grain is self sharpening it will give a cleaner cooler cut

- Choose a disc with a grinding aid. Grinding aids are built into the resin component of the disc and reduce friction and heat build up during use

Correct Product Use

- Do not apply too much pressure or dwell on one area for too long. Use a sweeping action to grind a larger surface so that the work is not concentrated in one area

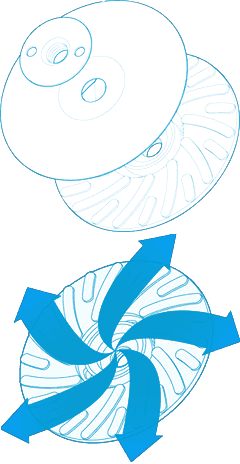

- Use an appropriate back up that increases airflow around between the disc and the backup pad which takes heat away from the work area

For more information regarding product use and safety tips, view our how-to video below.

Size and Shape

The three most common sizes for resin fiber discs are 4.5”, 5”, and 7”. Resin fiber discs are also available in other sizes if necessary. A typical arbor hole is 7/8” with the exception of 4 inch discs having arbor holes with the size of 5/8″. The discs usually have slots radiating out from the center to allow the disc to conform better to the locking assembly of the back up pad. Another common feature is a contoured profile which can help keep the disc flat during storage.

Be sure to check out our social media pages on Linkedin and Facebook to keep up with our weekly updates!