Product Spotlight: FLAP WHEELS & BELTS

FLAP WHEELS

Small abrasive flaps are projected and bonded to a central hub to create Flap Wheels. Available in mounted or unmounted, Flap Wheels are designed for light finishing, deburring, and flash removal. Most wheels are X-weight aluminum oxide cotton cloth. Exceptions to this would be J-weight cloth for increased flexibility, and silicon carbide for special applications.

Mounted flap wheels are available with a ⅛” or ¼” straight shank or a ¼-20″ male threaded shank. They are generally 3” or less in diameter and used on portable tools.

Unmounted flap wheels flaps radiate outwards from a central core, have an arbor hole, and are mounted onto a spindle with flanges. They are 4″+ in diameter and used on stationary tools.

ARC’s flap wheels add additional margin to your bottom line with their exceptional value-to-performance ratio.

- Triple flexed material

- Contours to work surface

- High-temp adhesive

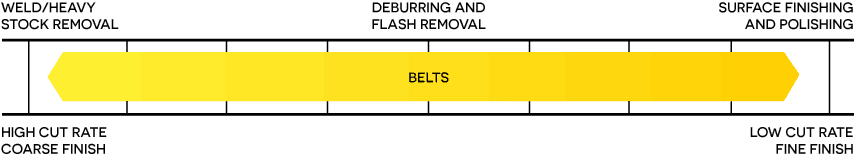

Belts

Belts are used in multiple applications from fine finishing of stainless steel coil to heavy stock and weld removal. In general heavy weight Y-weight are used for stock removal whilst flexible J-weight is used for fine finishing and contour work.

With sizes ranging from 1/8” wide to 600” in length in multiple grains and backings, we can deliver nearly any belts needed for your required application. The ARC ABRASIVES, INC. Custom Belt Program has set the industry standard. Our custom services and excellent application knowledge make it easy to deliver solutions directly to your shop floor.

- Proprietary non-woven

- Low-stretch, scrim back, and flex

- Airfile, MRO, Productio, & Wide

Determine the right size and grit for you by viewing our common belt and flap wheel sizes here.

Also be sure to check out our social media pages on Linkedin and Facebook to keep up with our weekly updates!