Resin Fiber Discs on Mild and Stainless Steel

Resin Fiber Discs are a flat disc used for heavy grinding and weld removal. They are used for similar applications as Flap Discs. Resin Fiber Discs consist of a stiff fiberboard backing coated with a single layer of resin and abrasive. ARC’s Resin Fiber Discs have grinding aids in both the AO and ZA products. This grinding aid helps performance and keeps the disc cooler during grinding. The discs have an arbor hole to allow them to be attached to a back-up pad which they are always used with. We recently created a case study of our discs on mild steel and stainless steel against top competitors that give very powerful insight with the performances.

Uses and Advantages

RFD’s are used for heavy stock removal on electric and pneumatic angle grinders. As they are 2-dimensional and only have a single layer of grit they have a limited life span. Once the grit has lost its sharp edge, the resin fiber discs can be discarded. Unlike flap discs no new abrasive is exposed as the surface wears down.

Correct Use of Resin Fiber Discs

Do not apply too much pressure or dwell on one area for too long. Use a sweeping action to grind a larger surface so that the work is not concentrated in one area.

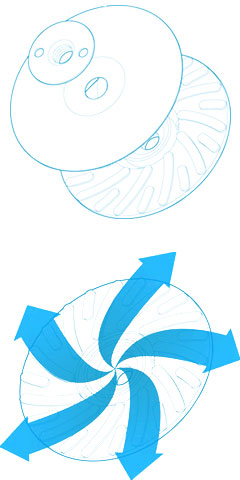

Use a Spiralcool back up that increases airflow around between resin fiber discs and the backup pad which takes heat away from the work area.

Size and Shape

The three most common sizes are 4½”, 5” and 7”. Also available are 4” and 91/8” but these are much less common. The arbor hole is usually 7/8” (only the 4” discs have 5/8” arbor holes). Additional to the arbor hole, resin fiber discs sometimes have slots radiating out from the center to allow the disc to conform better to the locking nut/washer assembly of the back up pad. Another common feature is a contoured profile which can help keep the disc flat during storage.

Check out our social media pages on Linkedin and Facebook to keep up with our weekly updates!