Weld & Corner Removal on Stainless Steel

This application process is in regards to any outside corner and open weld that is 3/8″ or larger, and referencing MIG welding. For few that are new to that process, MIG (Metal Inert Gas) welding is a process where a continuous solid wire is fed through a welding gun into the weld pool, and joins the two base materials. The advantages in using this method create a faster and higher quality product that is ready for shaping and stock removal.

Our Recommendation for Removal

We recommend the use of zirconia in lower grits for the removal of stainless steel plate and structural weld that is 3/8″ or larger. Heat related to the material is not as important in plate as it is stainless sheet material. However, abrasive media will become hotter than mild steel, so zirconia with a grinding aid will respond well under high heat and pressure applications. Use lower grits to rapidly remove a weld on place and structural stainless steel. Zirconia in this instant will perform better than Aluminum Oxide and offers a cost advantage over ceramic, as heat is not a concern because the heat is dissipatied from the thickness of stainless steel.

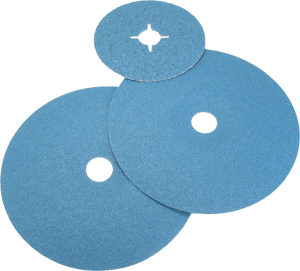

Commonly Used Products to Remove Weld & Corners

The majority of the process to remove weld and corners will see that the use of a right angle grinder is used, with a backing pad and abrasive. Resin Fiber Discs are preferred and used on contoured shapes, such as rolled plates and tanks, where flap discs work better on straight corners and flat shapes. Quick-loks, resin fiber discs and 5/8″-11 flap discs are used as well.

Check out our social media pages on Linkedin and Facebook to keep up with our weekly updates! Be sure to check out our previous posts in our Daily Grind blog as well!