Case Study: Quick-Loks and the Aerospace Industry

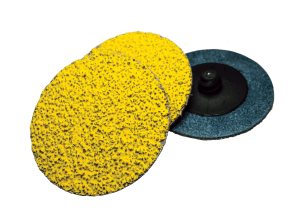

ARC Abrasives teamed up with a leading aerostructure manufacturer to test the effectiveness of PREDATOR™ quick-loks to their current quick change discs. Our quick-lok products were tested on an AP Bulkhead Engine Mount using a right angle die grinder. To learn more, download the white paper to read about how ARC helped increase production and efficiency to further impact their bottom line.

Challenges

The primary focus was to compare the performance of our quick-loks to the current discs being used. Their current quick-change discs had issues with overheating, burning, and glazing. The titanium particles would start to melt and fly off the disc, creating massive safety concerns. Among those safety concerns was their filtration systems ingesting hot dust particles.

Application

Operators were able to use a PREDATOR quick-lok on the engine mount with a right angle die grinder. The disc showed a noticeable improvement on the cut rate and longevity, getting the application done with 1 disc as opposed to the usual 3 discs.

Conclusion

Changing to our PREDATOR quick-loks brought on a 68% increase in efficiency and production. The best outcome came from the $220,000 in savings in parts alone from the performance increase. Safety improved immensely from the 40% decrease in dust and reduced titanium slag.

PREDATOR™ Quick-Loks outlast the competition by adding additional self-sharpening grains to the top layer of the disc. The integrated grinding aid provides a long lasting, aggressive cut for the life of the disc.

Also check out our social media pages on LinkedIn and Facebook to keep up with our weekly updates!