Coated abrasives are made by bonding an abrasive grain to a backing material using a make coat of resin. A second coat (size coat) of resin, and sometimes even an additional coat (top size coat), is applied. After curing in an oven, the material is converted into various types of abrasive products including sheets, discs, fiber discs, rolls, belts, flap discs and flap wheels.

ARC’s coated abrasives are used in an extensive range of applications from grinding and deburring to surface prep and finishing.

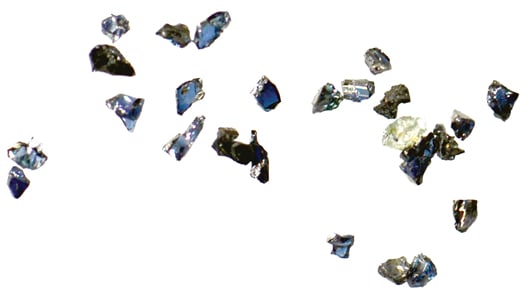

GRAINS

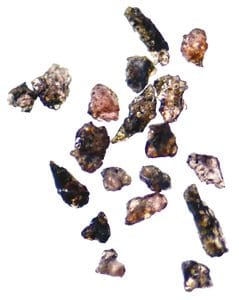

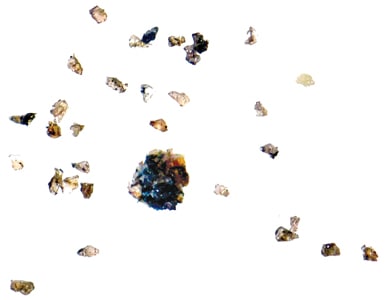

The cutting power of an abrasive grain depends on shape, hardness, toughness and orientation. All four factors control the penetration of cut and the life of the grain. The shape of the grain governs the cutting efficiency. Sharper grains produce a cleaner cut and tend to stay cooler during use. Blocky grains give a rougher cut and create more friction. Different applications require different types of abrasive grain.

ALUMINUM OXIDE (AO)

Fused aluminum oxide is the most common abrasive grain in use today. AO is tough and durable, with no clearly defined crystal structure. As the grain wears, it produces rounded edges reducing cutting power. Brown aluminum oxide is the usual grain for coated abrasives products but its also available in white, pink and other variants.

ZIRCONIA ALUMINA (ZA)

Zirconia alumina is an alloy of aluminum oxide and zirconia with a crystalline structure. Under heat and/or pressure, the structure fractures producing a new cutting edge and longer cutting life.

COMPACT GRAIN

Individual grains are clustered together to form a larger grain shape. This type of construction provides extended life compared to conventional abrasives. Compact grain is ideal for finishing applications on any metal in belt, PSA and quick-lok disc form.

SILICON CARBIDE

Silicon carbide is the hardest of all common abrasive materials. It is sharp, but friable, making it fast cutting, but short lived. It is ideal for use on non-ferrous metals like aluminum, brass, bronze, magnesium and titanium. For final finishing, the sharp crystal structure produces fine, straight edged grind lines that reflect light better than the rounded aluminum oxide grind lines.

CERAMIC

Ceramic aluminum oxides are formed via a chemical process. The grain consists of millions of smaller crystals, which fracture off during use and continuously form a new cutting surface. This self-sharpening process requires heavy pressure to ensure that the grains do not glaze.

BACKINGS

The type of backing is determined by the amount of strength and flexibility the abrasive must provide. The basic types of backing are paper, cloth, fiber and film.

Paper

Paper is used where low product cost is preferred over strength and toughness. Papers are made to tight weight tolerances gauged by the weight (lbs) per paper maker's ream: 480, 24” x 36” sheets.

Heavier papers are less flexible, more tear resistant and suited to mechanical applications. The lighter papers are flexible and better suited for hand sanding operations and finer finishing. Paper is used for extremely fine grits where any surface imperfection in the substrate would cause inconsistent sanding patterns in the polishing applications. Paper can also be made waterproof by the addition of latex and other water resistant resins.

Suggested Applications:

Heavier mechanical to flexible hand sanding operations. Available in waterproof for more specialized applications.

Cloth

Cloth substrates are more expensive than paper and structurally stronger making them well suited for mechanized operations, such as belts, discs and wheels.

The first two cloths in the US market were cotton drills (X-wt.) and cotton jeans (J-wt.). The next advancement was a heavier weight drill commonly known as Y-wt. More recently double Y or H drills have been used for heavy grinding applications.

Sometimes an F is added as a suffix to denote extra flexing (e.g. JF and XF).

While cotton was the first cloth, synthetic cloths, polyester and polyester/cotton mixes have become more prominent as they are stronger and more stable in use. The synthetic polyesters are inherently waterproof while the cotton products need treatment to be waterproof.

While fabric weight indicates stiffness and strength, back filling and flexing also provide a role. Back filling ensures adhesion between the fabric and the adhesive coats of the manufacturing process and fine tunes the abrasives' final properties.

Suggested Applications:

Mechanized belt, disc or wheel applications.

Vulcanized Fiber

Vulcanized fiber is made from cotton rags and treated with harsh chemicals to form a gelatinous substance. This mixture is layered into plies that are heat vulcanized and calendered to create a strong, stiff base material. Vulcanized fiber products are used in disc form, such as resin fiber discs, for heavy duty stock removal in grits 80 and coarser.

Suggested Applications:

Resin fiber discs for aggressive operations.

Film

Films can be made with exceptional flatness and tight thickness tolerance making them suitable for technical operations. Film is also tear-resistant and waterproof.

Suggested Applications:

Fine grinding with tight tolerances and most technical operations.

NONWOVEN

Non-woven abrasives feature a flexible, 3-D webbing embedded with abrasive grain. As a non-woven product glides over a contoured surface, the webbing compresses and expands, allowing the grains to reach the entire surface. Non-woven products are less likely to damage a work piece, and can provide a uniform finish to contoured surfaces without compromising critical tolerances. This is especially important during a finishing process.

The conventional method for removing deep scratches involves using a progression of coated abrasives, e.g. 80, 120 and 180 grit, each providing a progressively finer finish. The conforming nature of non-woven abrasives removes scratches while providing a fine, uniform finish. This reduces the number of steps needed in the process and provides a major savings in labor costs. In addition, the open structure of a non-woven repels loading and their synthetic components are waterproof and resistant to metalworking chemicals.

Z-WEB represents ARC’s family of high performing 3-D products used for finishing, light grinding and masking applications on materials such as Stainless Steel, Titanium and Exotic Alloys. Z -WEB products deliver a consistent and efficient final finish without damage due to excess stock removal, overheating or smearing.

SURFACE CONDITIONING

Surface conditioning is usually performed near the end of a manufacturing process and refers to changing a product's surface without damage to its base material.

ARC's surface conditioning materials (SCM) feature all the benefits of a non-woven structure with one-sided scrim reinforcement. The addition of scrim adds strength to discs and belts used in high speed operations.

ARC's surface conditioning products include Z-WEB discs and belts whose open 3-D structure resists loading and delivers long lasting performance with a uniform scratch pattern.

Cleaning & Finishing

Non-reinforced, or clean and finish (C&F) products are made of a non-woven base without a woven scrim and are typically hand-operated products. Their open web construction resists loading and may be rinsed clean and used repeatedly. ARC's clean & finish products are designed for general purpose cleaning, prepping and finishing and are offered in a variety of grades and sizes. They include hand pads, sheets, rolls and flap wheels.

Unitized

Unitized wheels feature a three-dimensional non-woven web design, where layers of non-woven fibers are filled with abrasive grain and resin then compressed and cured. Unitized wheels are bi-directional, and often used on portable tools or stationary grinding machines.

Available in a variety of densities and grades, our Z-WEB unitized wheels are an excellent choice for a wide range of applications in deburring, polishing and finishing.

Z-WEB unitized wheels deliver high quality, long lasting performance with consistent final finishes.

BONDED

Bonded abrasives are comprised of a mix of abrasive grains, fiberglass and bonding materials made into wheels and used on hand held machines such as angle grinders, petrol saws and straight grinders.

As the wheel spins against the surface of a work piece, the grains fracture and wear away. As the top layer wears, a new layer of grains is exposed and the wheel continues to shrink in diameter.

Used primarily for cutting applications and aggressive stock removal, ARC’s bonded category of abrasive products includes cut off wheels and powerful grinding wheels for an extensive variety of metalworking applications.

ARC's cutting discs are used in a variety of applications, from precision cutting of thin materials to high-performance cutting operations using our PREDATOR self-lubricating disc. Cutting discs are available in both flat shape (type 1) or with depressed center (type 27).

ARC's grinding discs are designed to remove high amounts of material from the work piece or for deburring operations, and are offered in a depressed center (type 27) shape.