Abrasive belts are used in multiple applications from fine finishing of stainless steel coil to heavy stock and weld removal. In general heavy weight Y weight belts are used for stock removal whilst flexible J weight belts are used for fine finishing and contour work. In fact J weight materials are not available in coarse grits (coarser than 60).

With sizes ranging from 1/8″ wide to 600″ in length in multiple grains and backing, we can deliver nearly any belt needed for your required application. The ARC ABRASIVES, INC. custom services and excellent application knowledge make it easy to deliver solutions directly to your shop floor.

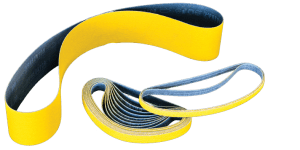

PREDATOR™

Quickly becoming our fastest growing product range, PREDATOR™ belts have a heavy Y-weight backing and proprietary grain structure, ensuring quality performance on a wide range of alloys. The combination of two grinding aids only reinforces its leading gram removal ratio.

PERFORMANCE COATING

Performance Coating is available for belts less than 12″ in width. This product enhancement will add additional performance in aluminum applications.

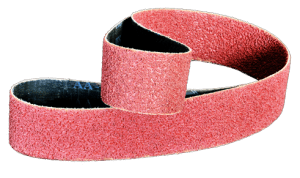

Compact Grain

Compact grain belts are best for finishing applications. With a grit range of 80 to 600, the clustered design delivers 3 to 1 performance when compared to conventional aluminum oxide products. Although aluminum oxide compact grain is excellent for mild and stainless steel applications, silicon carbide compact grin offers some of the industry’s best grinding ratios for herder titanium and nickel alloys.

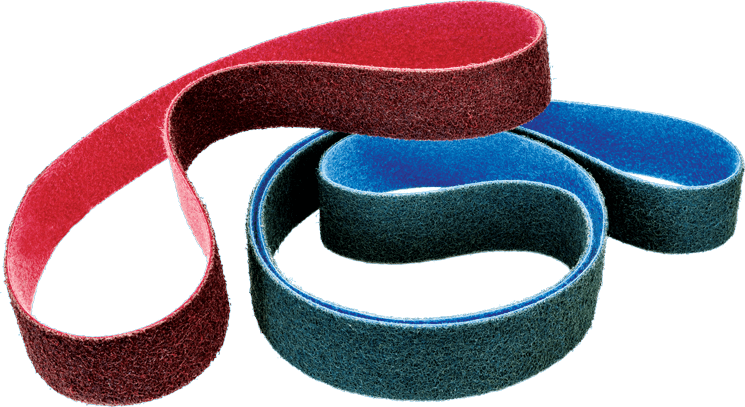

Z-WEB™ Surface Conditioning

Z-WEB surface conditioning belts are suitable for various grinding and sanding operations, from mild stock removal to fine finishing. Our surface conditioning belts come in a wide range of sizes and can be customized to meet the size requirements of almost any tool or machine.

Want a free sample?

If you are further interested in our product, you can fill out a form below to receive a sample. Let us know how our product does!