Elevating Aerospace with Premium Cartridge Rolls

ARC ABRASIVES is changing the game by adding the latest in ceramic grain technology to their abrasive line. ARC® Premium Ceramic Cartridge Rolls attack the metal working industry with enhanced cut ratios, longer life, and cooler operation.

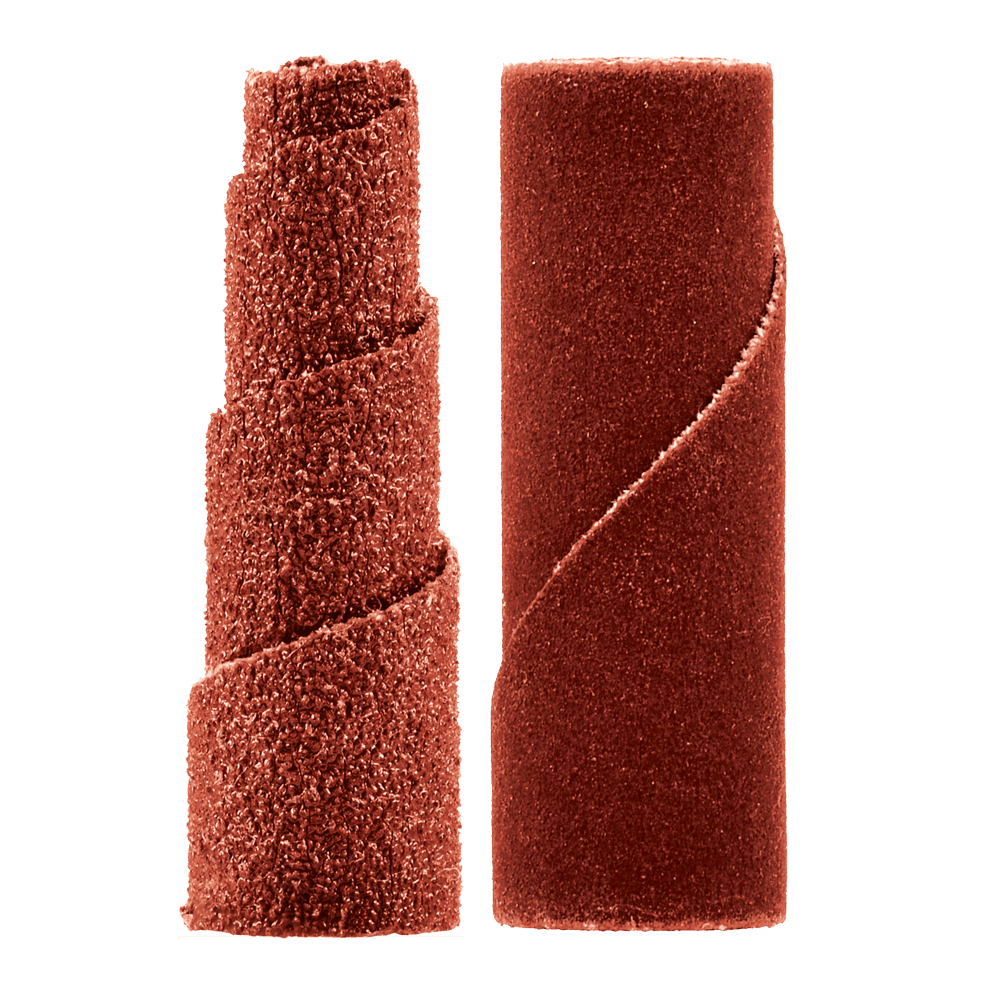

ceramic cartridge rolls

Premium Ceramic cartridge rolls last twice as long and provide a balance between fracture behavior and stability. Cartridge rolls are commonly used for their flexibility in small areas. The top-sized ceramic grain contours to the surface of stainless steel, titanium, and exotic alloys.

Cartridge rolls in the aerospace industry

Cartridge rolls are used in general applications that help remove machine marks and weld waves in tight areas. Titanium is primarily used in aerospace for the corrosion resistance and low thermal conductivity. While these properties are helpful for the industry, this makes it difficult to find a good abrasive match for the heat-sensitive material. Using ceramic cartridge rolls allows the user to provide consistent cutting action while maintaining a lower grinding temperature, making ceramic abrasives a force to be reckoned with.

THE ADVANTAGES OF CERAMIC ABRASIVES

Ceramics are known to be very tough, sharp and long-lasting. ARC’s Premium Ceramic grains combine the latest in grain technology with proven results when used on stainless steel or exotic alloy applications. The Nano-Fracture Technology allows for small pieces to break away during the process of grinding. The sequential phased breakdown of the ceramic grain provides unique advantages, including:

- higher metal removal rate

- faster cutting speeds

- lower grinding temperature and less friction

- shorter cycle times and fewer equipment changes

- minimized operator fatigue

- reduced cost per part

- excellent cost/performance ratio

Check out our social media pages on Linkedin and Facebook to keep up with our weekly updates!