Engineered Solutions: Z-Web Quick-Loks Case Study

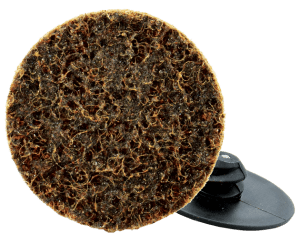

ARC Abrasives teamed up with a tire and auto shop to test the effectiveness of Z-WEB™ quick-loks to their current surface conditioning quick-change discs. Our quick-lok products were tested on rust and corrosion build-up on a customers’ brake assembly. To learn more, download the white paper to read about how ARC helped increase production and efficiency to further impact their bottom line.

Challenges

The primary focus was to compare the performance of our quick-loks to the current discs being used. Some of the most critical challenges the company faced involved numerous safety issues. Their current quick-change discs did not fit securely in the die grinder, causing the discs and r-lock nipple to break and fly off while in use. Any broken r-lock pieces lodged in the grinder had to be removed with a heated chisel.

Excluding safety issues, discs still had difficulties reaching the tight corners and crevices of the brake assembly. This issue caused their discs to buckle and fold from the applied pressure. Although the currently used disc was getting the job done, questions were raised in the possibility of a more efficient product that could increase input while improving safety and performance.

Application

Operators were able to use a Z-WEB coarse disc on a customers’ brake assembly, focusing on the corroded aluminum calipers. The disc showed a noticeable improvement on stock removal and blending. Operators had no problem reaching the tight corners and crevices, and were able to finish the job with peace of mind from the disc being secured in the die grinder.

Conclusion

Changing to our Z-WEB quick-loks brought on an annual $335,000 in savings. The best outcome came from the improved safety and performance, resulting in a 66% output increase. The Z-WEB discs staying on the die grinder has eliminated the need to use a heated chisel, saving 1 hour per work day.

Also check out our social media pages on LinkedIn and Facebook to keep up with our weekly updates!