Flap Wheels: Abrasive Product Spotlight

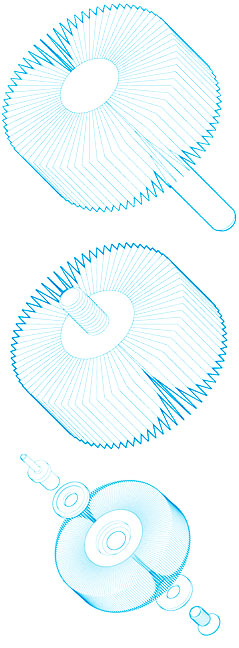

Flap Wheels are available as mounted or un-mounted products. Mounted flap wheel are generally 3” or less in diameter and are used on portable tools. Unmounted flap wheels are 4” and larger in diameter and the larger wheels are used on stationary tools.

Flap Wheels are designed for light finishing, deburring and flash removal. The flap design allows the wheel to contour around the work piece and smooth the surface. As the flap wears away new abrasive grain is exposed and the wheel continues to cut.

Flap Wheel Performance

Mounted Flap Wheels are available with a ⅛” or ¼” straight shank or a ¼-20 male threaded shank. The ⅛” shank is used in the mold and die industry for precision work with MFW in the diameter range 3/8” to 1 3/16”. ¼” straight shank and a ¼-20 threaded shanks are the most common shanks for general usage.

Unmounted Flap Wheels

Unmounted flap wheels have the same arrangement of flaps radiating outwards from a central core. UMFW have an arbor hole and are mounted onto a spindle with flanges. UNFW can be as wide as 16” diameter with a face width of 4”.

Abrasive Material

The pressure used in grinding and finishing with a flap wheel does not justify ceramic or zirconia grain as no increase in performance would be seen. As such nearly all wheels are X-weight aluminum oxide cotton cloth. Exceptions to this would be J weight cloth for increased flexibility and silicon carbide for special applications such as aerospace. Aeronautical engineers do not use recommend AO products due the high iron content in the mineral. If used on aero part the iron could contaminate the metal and become the source for crack to propagate under high stress conditions.

Nonwovens are typically used in flap wheel form to impart a brushed or satin finish. Combination flap wheels of coated abrasive and nonwoven are also used as a slightly more aggressive version than a 100% nonwoven wheel.

If you would like more information on our company, please check out our social via Facebook and Linkedin.