Flap Wheels: Product Showcase and Spotlight

Flap wheels are an abrasive product that is used for metal finishing. This product is made of projecting small flaps that are bonded to a central hub. Flap Wheels are available as mounted or un-mounted products. ARC’s flap wheels add additional margin to your bottom line with their exceptional value-to-performance ratio. For more information, check out our flyer that showcases the full product list to better suit your needs.

Flap Wheels are designed for light finishing, deburring and flash removal. The flap design allows the wheel to contour around the work piece and smooth the surface. As the flap wears away, new abrasive grain is exposed and the wheel continues to cut. They are generally 3” or less in diameter and are used on portable tools. Unmounted versions are 4” and larger in diameter, and the larger wheels are used on stationary tools.

Flap Wheel Performance

Mounted Flap Wheels are available with a ⅛” or ¼” straight shank or a ¼-20″ male threaded shank. The ⅛” shank is used in the mold and die industry for precision work with mounted in the diameter range of 3/8” to 1″-3/16”. ¼” straight shank and a ¼-20 threaded shanks are the most common shanks for general usage.

Unmounted Flap Wheels

Unmounted flap wheels have the same arrangement of flaps radiating outwards from a central core. Unmounted wheels have an arbor hole and are mounted onto a spindle with flanges. These products can be as wide as 16” diameter with a face width of 4”.

Abrasive Material

Most wheels are X-weight aluminum oxide cotton cloth. Exceptions to this would be J-weight cloth for increased flexibility, and silicon carbide for special applications such as aerospace. Aeronautical engineers do not use recommend AO products due the high iron content in the mineral. If AO is used on aerospace parts, the iron could contaminate the metal and crack under high stress conditions.

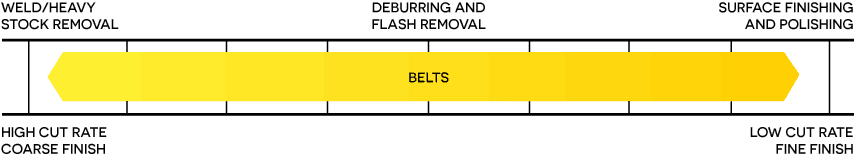

Belts and Application

Belts are used in multiple applications from fine finishing of stainless steel coil to heavy stock and weld removal. In general heavy weight Y-weight are used for stock removal whilst flexible J-weight is used for fine finishing and contour work. In fact J-weight materials are not available in coarse grits coarser than 60.

With sizes ranging from 1/8” wide to 600” in length in multiple grains and backings, we can deliver nearly any belts needed for your required application. The ARC ABRASIVES, INC. Custom Belt Program has set the industry standard. Our custom services and excellent application knowledge make it easy to deliver solutions directly to your shop floor.

Our full product list will help determine what the right size and grit is for your margin and bottom line.

Be sure to check out our social media pages on Linkedin and Facebook to keep up with our weekly updates!