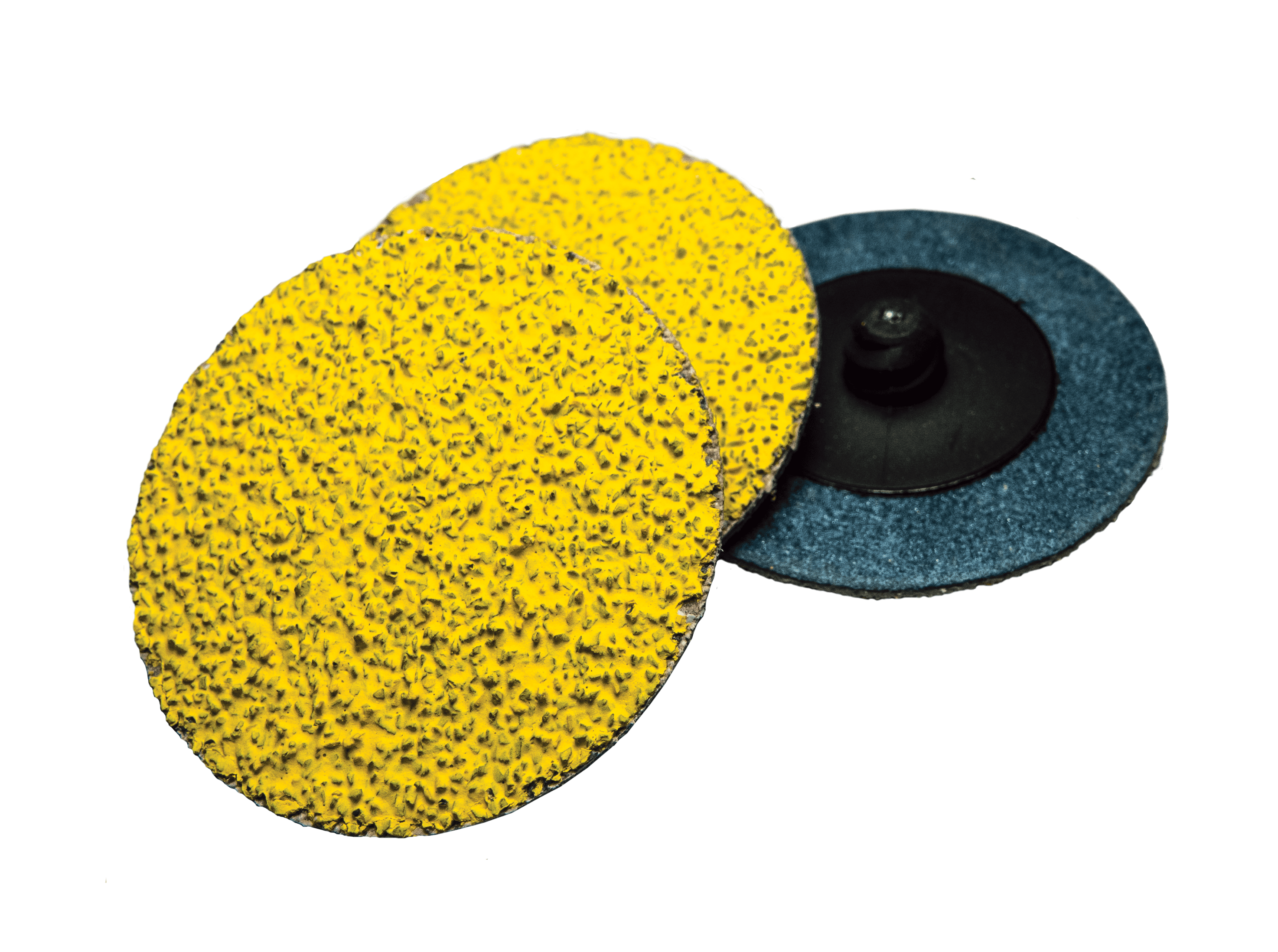

Core Product Focus: Quick Change Discs

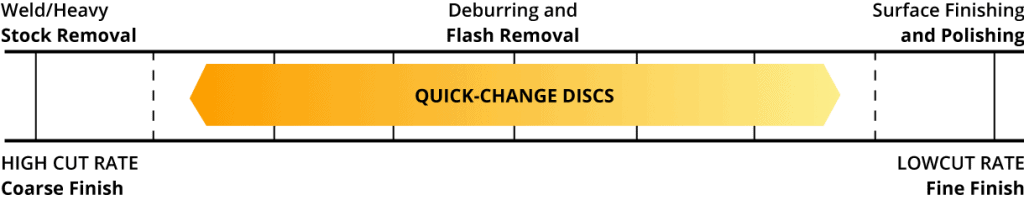

Quick-Change Discs are small discs with a button on the reverse side. The button allows the disc to be changed quickly with one twist, and without the use of special tools. The two popular button styles are known as type R and type S. Reduced operator fatigue and shorter cycle times are some of the advantages the product has to offer. Quick-change discs are available in coated and non-woven abrasive backings.

PREDATOR™ Quick-Change Discs

PREDATOR quick-lok discs outlast the competition by adding additional self-sharpening grains to the top layer of the disc. The dual grinding aid layers increase life by providing a cooler working surface. It offers an aggressive cutting action that’s ideal for mild steel applications.

Z-WEB™ Quick-Change Discs

>Z-WEB quick-change discs are engineered with polyurethane resin to prevent smearing and provide a smoother operation. This product is considered waterproof material that allows for both wet and dry applications.

Uses and Advantages

The main advantage of any quick-change discs are the mechanisms providing product changeover, helping with minimal downtime and reduced operator fatigue. The small diameter of the disc leaves a small grinding footprint and allows the user to grind in restricted areas that a larger tool could not accomplish. The standard ARC disc is an X or Y weight abrasive with a single layer of Maxback laminated to the reverse side of the disc.

The more flexible a disc the greater it’s ability to conform to the surface being finished and the lower the cut rate. The more rigid the disc the higher the cut rate and stock removal but the less conformability.

Quick-Lok Flexibility

The standard ARC disc is an X or Y weight abrasive with a single layer of Maxbak laminated to the reverse side of the disc.

Increased flexibility and rigidity can be attained by any of the following methods:

Undersize Holder

Over 95% of Quick-Lok sales are for 2” or 3” discs. We recommend using a 2” disc with a 2” holder. However it is common practice to use an undersized holder such as a 1” or 1½” holder with a 2” disc to enable the disc to flex and contour around the workpiece.

Hardness of Holder

Flexibility can also be varied by using different hardness back up pads. ARC’s 2” and 3” backup pads are available with soft, medium and hard rubber.

Other methods to change the flexibility of the discs are slotted edges, multiple plies of backing, and variable stiffness backing where the edges are designed to be more flexible than the center.

Choice of Backing

ARC typically uses 0.8mm fiberboard as the standard Maxbak backing, ARC also has a lighter, more flexible backing as a on the AO/X+ Flexible discs. For increased rigidity, ARC has a line of “Resin Fiber Disc” Quick-Loks available in aluminum oxide and zirconia.

Recommendations

2″ and 3″ sizes make up overall sales for the discs . ARC recommends using a 2″ disc with a 2″ holder. However, it is common practice to use an undersized holder to enable the disc to flex and contour around the work-piece. ARC typically uses an 0.8mm fiberboard as the standard Maxbak backing, but other options are available.

Our PREDATOR Ceramic Hybrid quick-change discs are available in the ARC Arrive 48-hour shipping program. ARC Arrive provides the metalworking industry a wide-range of our most popular and in-demand products with reliable shipping times, coupled with performance that exceeds market expectations. To learn more, head to the ARC Arrive promotional page.

Check out our social media pages on Linkedin and Facebook to keep up with our weekly updates!